Standard export packaging:

1. Apply anti-rust oil to the equipmenteasy rustypart and carry out anti-rust treatment.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-movepart of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

5. Use New Zealand imported bluish pine wood or American Douglas fir wood as the bottom support, 12mm multi-layer plywood for side panels, all wood fumigated. We cooperated withexperienced and professionalexported wooden packaging manufacturing enterprises to make final package.

Machine advantages:

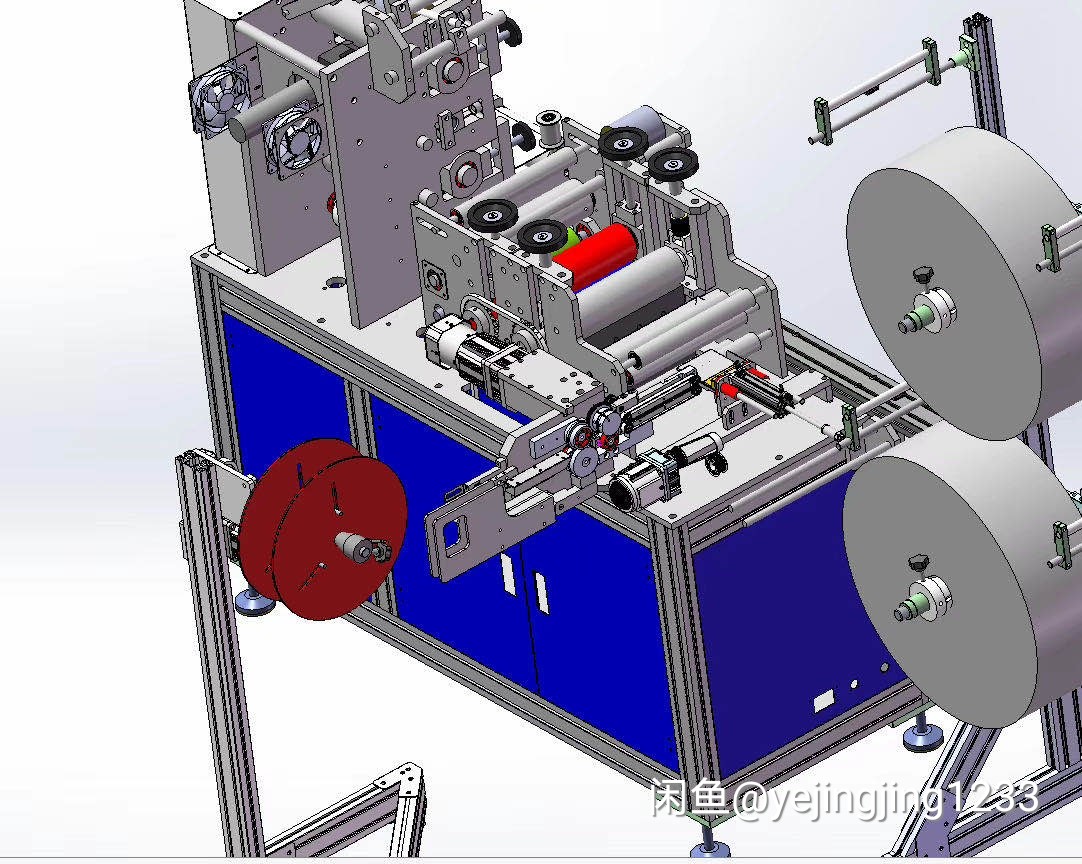

1. Cutting roller

We use the chrome steel to cover the rubber roller both sides .So that the rubber is not crack from side after extended periods use.

2. Traction roller

We use the silicone rubber materials instead of the butyronitrile materials .The silicone rubber materials is good abrasion

resistance and will not crack

3. PLC touch screen

We use DELTA group brand PLC touch screen .

4. Mask nose strip tension controller

We use Mask nose strip tension controller .This device can avoid the nose strip differ in length .

5. Nose strip straight- feeding device

We use Nose strip straight- feeding device , It can ensure the nose strip be feeded straightly in the processing, so the finished

mask will be flat and artistic.

7. Non woven raw materials sensors

We use Non woven raw materials sensors,once the raw materials use up,machine will stop automatically

8. Raw materials tension controller 1

We use the Raw materials tension controller to avoid the materials plugging .

9. Raw materials tension controller 2

Our machine is equipped with two braking ways . One is belts pressing and another is screw fixing . You could choose either one or use both according to your need.

10. Raw materials EPC device

We use raw materials EPC device ,to do materials adjustment.

11. Machine door lock

We just door lock ,with out the key,worker can not start the machine.

12. Frequency converter

We use DELTA group brand frequency converter .

13. Machine body and materials feeding connect board,We connect Machine body and material feeding frame with connecting boards,so that the running of whole machine will be very

stable.

14. Electrostatic eliminator

In our machine we have one electrostatic eliminator . to eliminate non woven mask surface static.

15. Machine motor

Our geared motor is new type and no need refuel.

16.Fan

We install the fan near the ultrasonic horn ,to Lower the horn temperatures,to to extend ultrasonic life.