| Items | Specification |

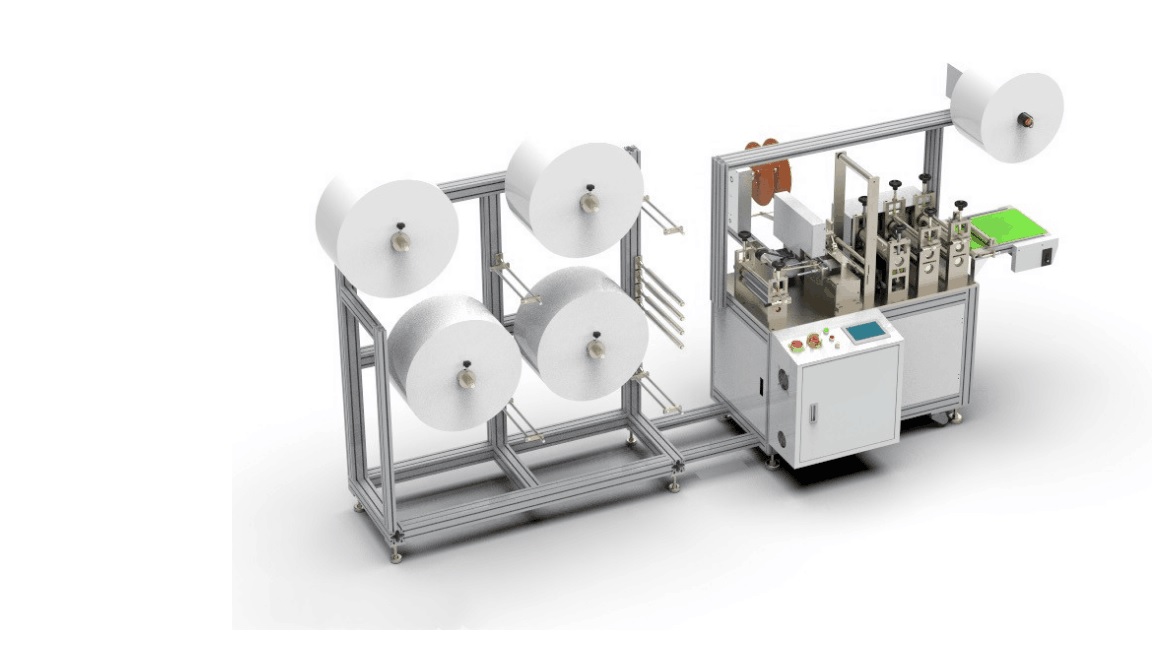

| Frame | Aluminum profile |

| Machine dimension | 6500(L)×4000(W)×2000(H).mm |

| Size of face mask | 175×95, mm(Adults) |

| Design speed | 130pcs/min |

| Production speed | 100pcs/min |

| Layers of the mask | 3~4 |

| Working efficiency | 95% |

| Power | 9Kw |

| Air pressure | Not less than 0.6Mpa |

| Compressed air consumption | 300L/min |

| Machine weight | About 1800KG |

| Protecting | There are protective hoods for transmitting parts |

| Weight capacity on the floor | Not more than 500kg/m2 |

Standard export packaging:

1. Apply anti-rust oil to the equipment easily rusty part and carry out the anti-rust treatment.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-move part of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

5. Use New Zealand imported bluish pine wood or American Douglas fir wood as the bottom support, 12mm multi-layer plywood for side panels, all wood fumigated. We cooperated with experienced and professional exported wooden packaging manufacturing enterprises to make a final package.

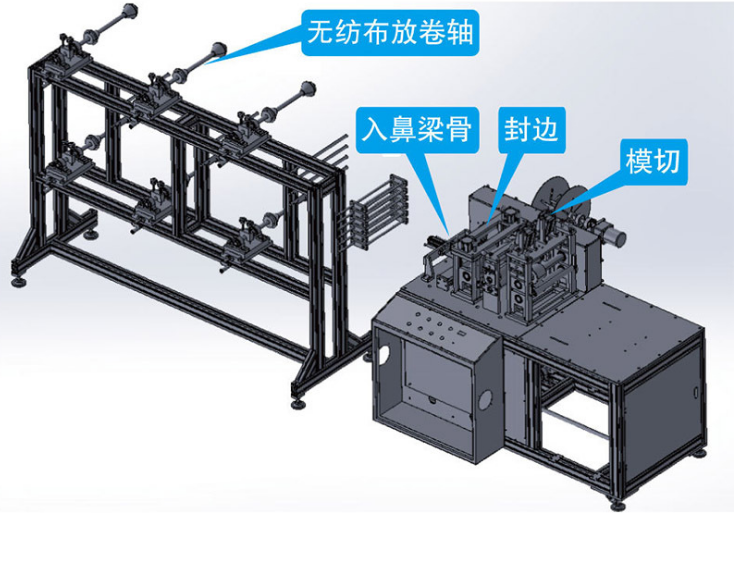

Features

1. There is automatic tension control for the raw material, and the tension balance can be ensured.

2. Fully Automatic Disposable Surgical Medical Face Mask Making Machine is made of aluminum alloy, it is stable, low failure, beautiful and strong, and there is no rust.

3. Fully Automatic Disposable Surgical Medical Face Mask Making Machine is PLC controlled, and with the servo driving, the automation is high.

4. There is the optoelectronic (fiber) detecting for raw material, and the waste is reduced.

5. Fully Automatic Disposable Surgical Medical Face Mask Making Machine can be used to produce facial masks (1~4layers).

6. There is the counting function (for the total amount & the batch quantity), and the batch quantity can be set freely.

7. By exchanging dies, facial masks with different sizes or types can be produced.

8. After the updating, processes of raw material feeding, nose bridge bar's cutting, mask edge's welding, the mask folding, the ultrasonic melting, the forming and the cutting, etc. can be automatic.

9. Some mechanical parts can be adjusted.

10. The pattern in the mask can be customized.

11. Activated carbon can be filled in the mask